The consumption of shoes in the world grows without stopping. According to the forecasts of the company Snipe It is estimated that in 2014 20,000 million pairs of shoes will be consumed of which it is clearly unknown what the impact they may have on the environment. Apparently the shoes, after the end of their useful life, are incinerated, which means emitting polluting gases into the atmosphere.

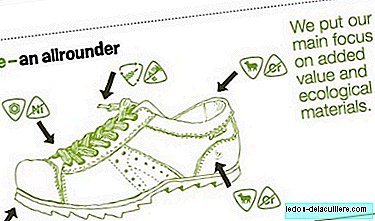

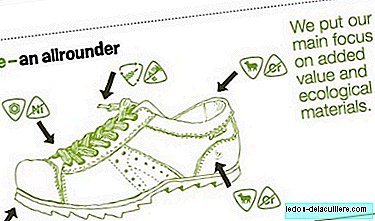

That is why the Snipe 100, which is 100% adaptable and 100% recyclable. It is a shoe that is manufactured in Portugal like the rest of the brand's footwear and for now it will only be sold in a single model and color, casual style, for men and women (you can see the shoe below in the image).

The idea of making a 100% recyclable shoe comes from Ernesto Segarra, owner of the old Segarra factory in the Castellón town of Vall d'Uixó and that began to turn the idea of having a shoe that did not generate waste in 1993. It seems to me that at that time the care of the environment , being important, he had not reached the levels of concern of today, so we can consider him a visionary and a great entrepreneur who was recognized by the Government of Valencia at that time. However, neither the market was ready for that green consciousness nor the materials: skins, soles, etc. they could work to obtain a 100% ecological and 100% practical shoe.

Finally, a joint work between the laboratory of the University of Vigo, the University of Pamplona that made the composting of materials and an industrial composting plant in Barcelona as well as many technicians and designers, have managed to develop the Snipe100 and have recently presented it, the September 5, at the footwear fair in Dusseldorf (Germany) and with great success as you can see in the video (in English) of the product. A pride for a product based on an idea and a 100% Spanish execution.

This is the shoe that can already be purchased at the Snipe store at a price of 150 euros.

Snipe also performs the tanning of the skin without using chrome This ensures that shoes are free of this type of toxic material. The manufacturing process is carried out with the tanning in titanium which is a metal without toxic effects and that degrades rapidly. Biodegradable thermoplastic materials are used for the soles.

According to Segarra it is a matter of time that compostable products applied to fashion are used. Thus, instead of throwing the shoe in the trash or incinerating it, it can be used to obtain homemade compost or recycle it in industrial composting plants.

For now, as we have commented, the product is starting with a single model and with boy and girl version. We hope and hope that the idea is extended by more products, also for children, and that our ecological awareness finds in Spanish innovation many answers to have sustainable products with our beloved planet.

I loved the news and I think the least is how the shoe is or what it costs. The challenge is to make these types of products increasingly familiar to us. and that we reduce the impact on the environment of those 20,000 million pairs of shoes that we mentioned at the beginning.

Here I leave the video, in English, of the product presentation: